Road Hubs

Main informations

Weight (gr)

Engagement points

Freewheel titanium grade

Price (€)

Tech informations

The hubshells, axles and caps are made from 7075T6 aerospace aluminium.

The entire freewheel is made from Grade 5 titanium.

The front hubs get a 100xQR axle.

The rear hubs get a 130xQR axle.

Front : 90gr

Rear : 189gr

Front : 20 or 24 holes.

Rear : 24 or 28 holes.

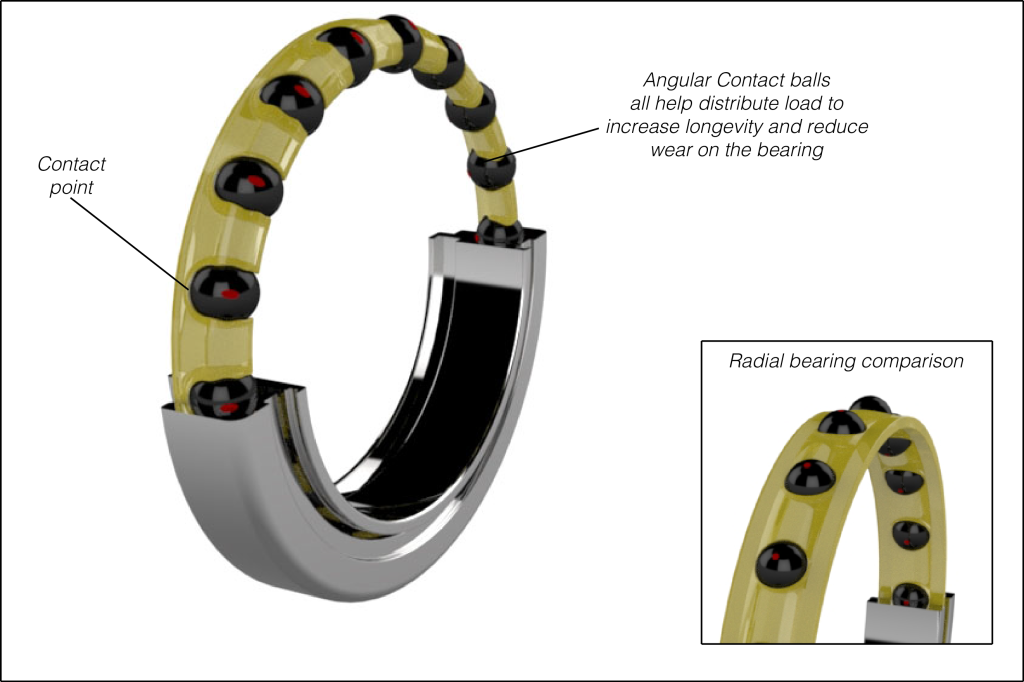

The bearings are from Enduro Bearings. We work with that company because it is the only one to produce hubs specific angular bearings.

In standard radial bearings, only 3 or 4 balls make contact during the load, at any given time. In angular contact bearings, all balls are engaged and spread the force over a larger surface aera, to decrease friction and minimize wear.

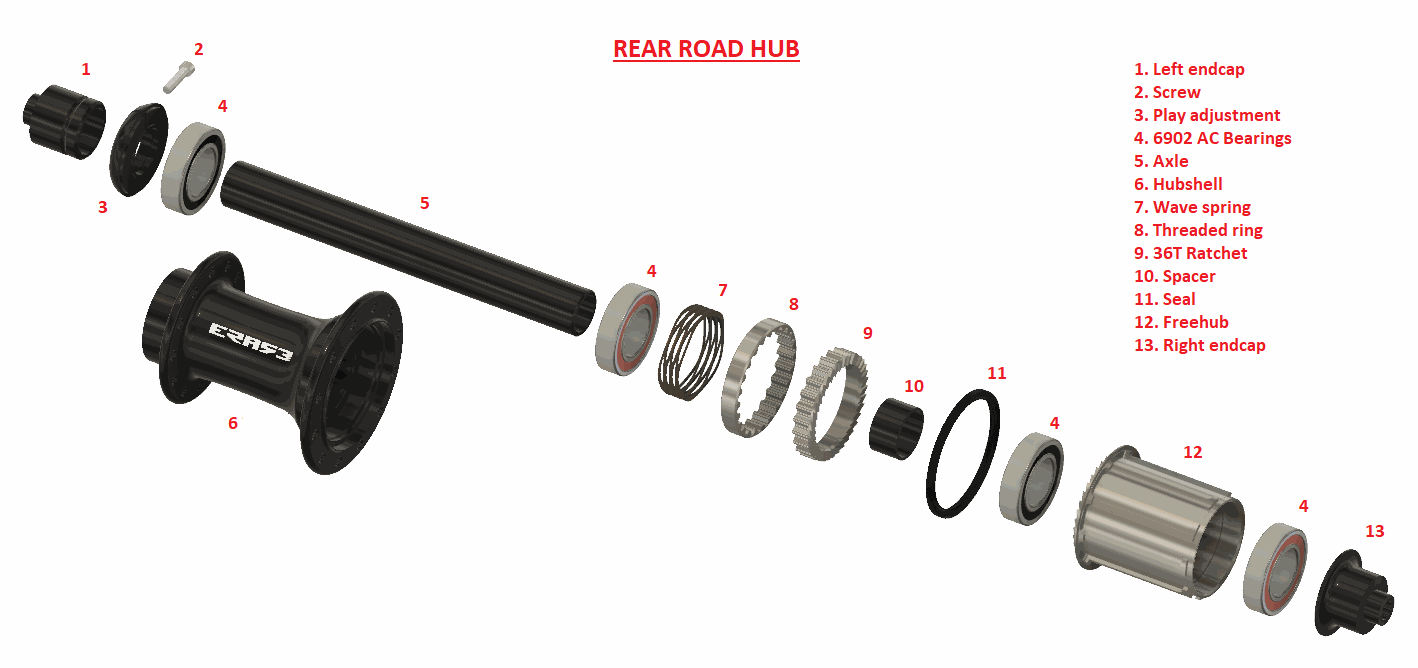

Front : 2x 6802

Rear : 4x 6902

Angular Enduro Bearings are designed for hubs with play adjustment like ours. This system allows you to tighten the hubs just enough to remove the play without putting any stress on the bearings. It will make the bearings smoother and more durable.

We use Grade 5 titanium to make the freewheel. Why? Because we didn't want to see anymore sprocket marks on the freehub.

The ratchet technology is the more reliable system because 100% of the system surface is working when you put power on your pedals.

- You can open hubs by hand just by pulling the end-caps off.

- You can pull the axle off through the bearings without need to remove one of them.

- When you pull the freewheel off the rear hub, every pieces stay in place.

- All pieces are large enough so that you'll never loose one of them, no thiny springs or little pawls.

- Since you don't need to thigh off the play adjustment piece to open the hub, you don't need to adjust it either when rebuilding it.

We didn't make any compromises and developped the hubs as we wanted it. But once the design was fixed, we searched the closest products sourcing and we are proud of this !

Aluminium : Belgium

Titanium : Belgium

Bearings : United States (for technical reasons, see "bearings")

Screws : Belgium

Seals ; Italy

Springs : Taiwan (for technical reasons, we are still searching an european company able to produce it)

Anodizing process : Netherlands

110€ for the front hub.

240€ for the rear hub.

Our hubs get a LIFETIME warranty.

- The warranty covers only product defaults.

- The warranty does not cover damage or failure caused by crash, misuse of the products, bearings and improper assembly or maintenance by an unauthorized dealer.

Only for the initial owner.

.jpg)